Custom Fabrication Capabilities

At Pierce Steel Fabricators, we have the facilities and equipment to handle just about any custom fabrication project. But the real key to our success is our people. Our staff is genuinely motivated to satisfy our customers with quality products. We have the experience and expertise in manufacturing custom products to ensure that our project will be completed on time, within budget to your requirements.

Quality & Inspection

Pierce Steel is committed to quality. All our projects endure a thorough inspection process including Inspection Test Plans (ITP’s) and weld inspections by an AWS Certified Weld Inspector (CWI). We provide 100% dimensional inspections and can provide additional quality assurance testing if needed. We offer NDE, load test, and pressure/hydro testing services.

Safety

The safety of our employees, subcontractors, customers and environment is our primary priority. We have designed a proactive and rigorous safety and training system to ensure that we comply with all industry standards.

We are ISNetworld and Avetta certified.

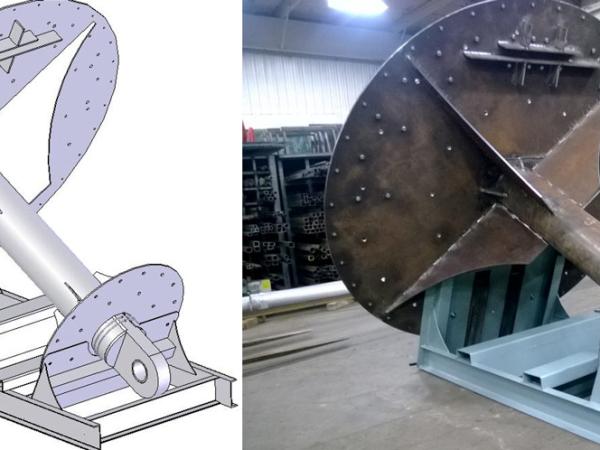

3D Modeling

Pierce Steel Fabricators is continuously striving for improvement to meet our customers specific needs at the best quality. Our engineering department uses state of the art 3D modeling design software. Our drafters can design a project from scratch or use our customers’ existing plan and supply a 3D rendering along with approval drawings for their review. This gives our customers a better visual of the project to review their requirements. The 3D modeling allows for quick and easy changes or additions to the drawings to eliminate any potential errors early in design process to avoid costly changes during shop fabrication or in the field.

Welding

We perform multiple processes of certified welding on all kinds of materials including carbon steel, stainless steel and aluminum. Our welders hold ASME and AWS welding certifications. All welders are inspected by our in-house Certified Welding Inspectors (CWI). Our certified weld procedures include:

- Gas Metal Arc Welding (GMAW) - Metal Inert Gas (MIG)

- Gas Tungsten Arc Welding (GTAW) - Tungsten Inert Gas (TIG)

- Flux Cored Arc Welding (FCAW)

- Shielded Metal Arc Welding (SMAW) - (Stick)

Laser Welding & Cleaning

Pierce Steel has extensive experience with laser welding of all types of metals. Our state-of-the-art laser welding systems offer several advantages over traditional welding methods, including:

- Precision: Laser welding allows for precise control over the heat input and the location of the weld, resulting in a high-quality and consistent weld joint.

- Speed: Laser welding can be performed at high speeds, which can result in shorter cycle times and increased productivity.

- Versatility: Laser welding can be used to join a wide range of materials, including metals, plastics, and ceramics, with minimal distortion or damage to the material.

- Reduced heat input: Laser welding typically involves lower heat input compared to other welding methods, which can help to reduce distortion, heat-affected zones, and overall thermal stress.

- Automation: Laser welding can be easily automated, allowing for greater consistency and efficiency in production processes.

- Less material waste: Because laser welding requires minimal heat input, there is often less material waste and lower consumable costs compared to other welding methods.

- Flexibility: Our system has built-in pre- and post-weld cleaning for producing higher quality welds.

Overall, Pierce Steel’s laser welding systems offer numerous advantages that make it a preferred welding method in various industries such as aerospace, automotive, medical, and electronics.

Plate Cutting & Punching

We have a high definition CNC plasma table with an 8’ x 20’ cutting area. We can cut any shape or size up to 2-1/2” thick carbon steel, 2” thick stainless and 2” thick aluminum. Our oxy-fuel torches can CNC cut up to 10” thick mild steel plate. We have a 10’ shear with capacity up to ½” thick. Our equipment also includes several ironworkers for cutting material to length and for punching holes and slots in material.

Plate Rolling

We have plate rolling machines with capacities of up to ½” thick x 10’ long. Our plate bending rolls are great for the fabrication of round tanks and vessels, heavy-duty ductwork and elbows, cones, cylinders and hoppers.

Plate Forming

We have multiple hydraulic press brakes including our 400 ton, 12-foot long-press with CNC back gauging system capable of forming 90 degree bends in 5/8” thick mild steel 12’ long.

CNC Tube and Pipe Cutting

Our CNC tube cutter accurately cut holes, notches, and other designs on round, square, and rectangular tubes, angles and channels. Capable of cutting 6” round and 4” square material, this unique tool allows us to generate a multitude of parts from various shapes, sizes and material types. Making difficult mitered joints, cutting holes for galvanizing and coping angles has become less taxing and more accurate than traditional methods.

Angle Bending Roll

We have the capability of rolling structural steel sections including angle iron, channel, I beams, flat bars, square bars, round bars, and pipe on our angle bending rolls. We can roll angle iron with the leg in or the leg out, channel and bar the easy way or the hard way.

Tube and Pipe Bending

We also perform tube and pipe bending. We bend up to 3” tubing and 2-1/2” pipe. We produce consistent quality bends in pipe, tube, squares, solids and other profiles. Our tube bending equipment is ideal for customized handrailing projects and other tube and pipe fabrications.

Saw Cutting

We perform saw cutting and mitering of all types of structural sections up to 18” tall x 22” wide on our vertical band saws.

Material Handling

We have 15 ton of overhead crane capacity as well as several forklifts and telehandlers for safely and efficiently processing all of our materials.

Painting

We have a dedicated paint booth for prepping and coating our products with corrosion control industrial epoxies, acrylics or oil-based finish paints and coatings.

Field Erection / Installation

We have the capability to field install any of the products that we fabricate. Our experienced team of on-site installation experts will come to your site to safely complete installation with minimum disruption to your production.

Machining

We also offer CNC machining services allowing us to manufacture your parts to the tightest of fabricated tolerances to meet your requirements.

Proudly building quality products in the U.S.A.

Pierce Steel Fabricators Inc. is proud of our rich history in building custom metal fabrications right here in the Good 'Ole U. S. A. All of our custom fabrication work is done at the manufacturing facility we have in Olean, New York and is made by our highly skilled American work force.

Made in the USA

We Support Veterans

What Our Clients Say

Thank you for the quick service. The sawhorses are perfect; we are very pleased with the units. When we need any additional of larger capacity horses, you are first on my list.

- Martin Plant Services, Chicago Heights, IL